Have you ever wondered about the difference between SMT and SMD in electronics? This can be a common mix-up, but the actual meaning of these terms is something really important to know for anyone interested in how electronic devices are made.

This article aims to clarify the air on this. If you are new to PCB assembly or are simply interested, knowing at least the basics of Surface Mount Technology and Surface Mount Devices will give you a good head start.

So, let us begin.

What is SMT (Surface Mount Technology)

Surface Mount Technology is a way of attaching electronic components directly onto the surface of a printed circuit board.

Unlike older methods using holes, SMT enables components to sit right on the surface of the PCB. It’s perfect for making electronics more diminutive, lighter, and more efficient.

Key Steps in SMT

- Applying Solder Paste: The process includes using a sticky mix of minute solder particles and flux, called solder paste, onto specific spots on the printed circuit board.

- Placing Components: Machines then place SMDs like resistors, capacitors, and ICs with accuracy on the solder paste. These machines ensure that everything is positioned right, which speeds up assembly and makes it more precise.

- Soldering:After that, the PCB with components is sent to a reflow soldering process. It is then carefully heated; this melts the solder paste, making solid joints between the SMDs and the PCB. These joints are solid and reliable once they cool down.

What are SMDs (Surface Mount Devices)

Surface Mount Devices are electronic components designed to be mounted directly onto the surface of a printed circuit board in the Surface Mount Technology.

These components are smaller than the traditional through-hole components and, hence, suitable for automatic assembly processes.

Advantages of SMDs

- Compact Size:SMDs are very small compared to through-hole components, hence developing more compact and light electronic designs.

- Efficient Assembly:They are suitable for automatic assembly using pick-and-place machines, which place them accurately and fast on the PCB.

- Performance: SMDs have demonstrated better electrical performance in many cases, compared to their through-hole counterparts, thus mostly suit high-density electronic applications.

Types of SMDs

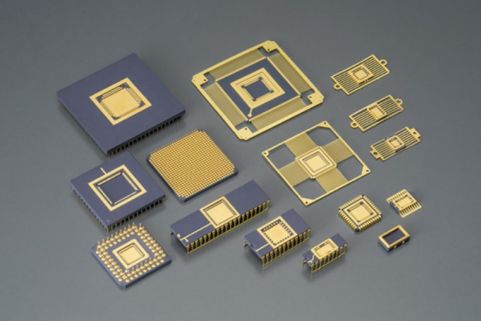

SMDs can vary from simple components, such as resistors and capacitors, to complex diodes and transistors, all the way up to sophisticated integrated circuits, or ICs; they also come with different package sizes and shapes, which are designed for different functions and space requirements in electronic circuits.

Key Difference between SMT and SMD

The main difference between SMT and the SMD is their purpose within electronic manufacturing.

1)SMT (Surface Mount Technology)

- Process: SMT stands for mounting electronic components directly onto a PCB’s surface.

- Application:This step involves the spreading of solder paste on specified areas of the PCB, the placement of the SMD components onto the solder paste through automated machinery, and lastly, reflowing or heating the assembly to form the solder joints.

2)SMD (Surface Mount Devices)

- Components:SMDs are the electronic components designed to be mounted on a PCB using SMT.

- Types: Resistors, capacitors, ICs, others—designed with compact size and automated assembly in mind.

Understanding the difference between SMT and SMD means distinguishing between a house-building process and just bricks as the material to make it on the other. The former, SMT, is the method used while building; the latter are materials or parts that enter into that very method.

This distinction is paramount to any person involved in electronics, be it a designer, engineer, manufacturer, or any other concerned with the efficient and effective exploitation of the modern assembly techniques.

Applications of SMT and SMD

SMT and SMD find wide applications in many modern electronic devices and industries.

- Consumer Electronics

Due to the compact size and potentially high efficiency of assembly, there are many applications for SMT and SMD in smartphones, tablets, and laptops, while wearables can also be added to the list.

- Computers

They form part of the basic makeup of the computer component, from motherboards to graphics cards and even memory modules, whereby dense circuitry is allowed to excel in performance.

- Industrial Electronics

In industrial-oriented applications, SMT and SMD components play essential roles when developing control systems, automation equipment, or medical devices where reliability and space-saving are crucial.

- Automotive Electronics

SMT and SMD find applications in the automotive sector for dashboard electronics, ECUs, and sensors—making advanced functionalities within confined spaces.

- Telecommunications

SMT and SMD technologies contribute to networking equipment, routers, and devices for communication through compact design and efficient data transmission.

Choosing Between SMT and Through-Hole Technology (THT)

In deciding between surface mount technology and through-hole technology for electronic assembly, several aspects are considered critical.

1)Component Availability

- SMT: Most modern components are only available in surface mount packages, providing more design choices.

- THT: This limits design flexibility, since some specialized components may only be available in through-hole versions.

2)Design Complexity

- SMT: Because of the smaller-sized components and their closely spaced mounting, SMT enables a higher density of circuits on the PCB.

- THT: The larger size of components and the need to drill holes in the PCB itself limit how dense the components can be on the board.

3)Production Volume

- SMT:This is the perfect process for producing bulk quantities since assembly processes are applied automatically, making it faster and more effective.

- THT: Suited for low to medium volumes where manual assembly or specific component requirements justify the use of through-hole technology.

4)Repair and Rework

- SMT:Often, the replacement of SMD components may prove to be very tricky because of both their tiny size and specific specialized tools that would be needed for their repair.

- THT: Generally, through-hole components are easier to remove and replace, so rework and repairs are easier.

By considering these factors concerning the particular project’s stringent requirements and production goals of the manufactured electronics devices, you can quickly identify the technology most appropriate for a given application to achieve optimum performance at minimum cost.

Conclusion

To sum up, understanding SMT and SMD is key in electronics. SMT mounts components directly on PCBs, while SMDs are those components. They bring benefits like smaller size, easy assembly, and better performance to electronic devices.