Ever wonder why none of your electronic circuits seem to work right? Capacitor polarity may be the issue. Keeping track of which end is positive and which is negative is crucial to avoiding damage to your circuits and ensuring they work correctly.

So in this article, we are going to explain what is capacity polarity in a detailed manner. Whether you’re a complete beginner or ready to refresh your mind, we’ll help you identify, understand, and correctly use polarized capacitors to keep your projects running smoothly.

So, let us begin.

What is Capacitor Polarity

Capacitor polarity refers to the orientation of the positive and negative terminals in certain kinds of capacitors. This orientation is very important for the proper functioning and operation of electronic circuits, especially when one is dealing with polarized capacitors like electrolytic and tantalum capacitors.

While non-polarized capacitors can simply be connected, polarized capacitors must be connected in the correct direction to avoid malfunction or damage.

Importance of Polarity

A polarized capacitor, if used with reverse polarity, can lead to serious consequences. The immediate risks include the fact that the circuit could be damaged by spurious failure or leakage or some other kind of explosion of the capacitor. This can compromise the safety of your project and the integrity of the whole circuit.

That means checking for the correct orientation of polarized capacitors is important both for the safety and functionality of your electronic devices.

Identifying Capacitor Polarity

It is pretty simple to identify the polarity of a capacitor if you keep an eye out for anything on the outside. The following are some methods beginners can easily practice:

Physical Markings

- Longer Positive Leg: Many polarized capacitors, especially electrolytic ones, have a longer leg indicating the positive terminal.

- “+” Symbol: Another common marking is a “+” symbol on the capacitor’s body, denoting the positive terminal.

Capacitor Type

- Electrolytic Capacitors: These often have a visible electrolytic cap and are clearly marked with a “+” symbol.

- Tantalum Capacitors: These usually have a stripe or a “+” sign to indicate the positive terminal.

Methods for Identifying Capacitor Polarity

Identifying the polarity of capacitors is quite important for proper functioning in your circuits.

Here are a few advanced methods you can use to properly identify capacitor polarities:

Deeper Dive into Polarity

Knowing the technical reasons for capacitor polarity is very important, especially with electrolytic and tantalum capacitors.

- Electrolytic Capacitors: These capacitors are polarized because they use an electrolyte that only allows current to flow in one direction. Usually, the positive terminal is constructed with aluminum foil coated with a layer of oxide. This oxide, therefore forms the dielectric member of this capacitor. Another terminal, called the cathode, mostly negative, is usually a liquid or a gel electrolyte. Polarity reversal can destroy the oxide layer and thus lead to a failure of the capacitor.

- Tantalum Capacitors: Tantalum capacitors are also polarized, again by the nature of their construction. The anode is tantalum metal, with a layer of tantalum oxide as the dielectric and a conductive solid or liquid electrolyte constituting the cathode. Since these capacitors are very sensitive to inverse voltage, they may short circuit or suffer a catastrophic breakdown if used with the wrong polarity applied.

Color Codes

Some capacitors have polarity marked using color codes, but this practice is less common and even somewhat unreliable.

- Color Coding: Some manufacturers color code the ends with different colored bands or markings to indicate the positive and negative terminals. However, these color codes vary greatly from one manufacturer to another and can be a cause of confusion.

- Reliability Issues: As the color codes lack standardization, it can be dangerous to rely entirely on them. It is always advisable to use a color code system in conjunction with other means of identification to avoid mistakes.

Datasheet Reference

It is indeed necessary to consult the capacitor’s datasheet to confirm polarity definitively.

- Datasheet Information: Manufacturers of capacitors write all information regarding their products on the datasheet, showing the exact specifications and intended applications based on their polarity markings. As such, datasheets become reliable sources of information for correctly identifying and using a capacitor.

- Importance of datasheets: In cases of uncertainties it is always important to refer to the datasheet about capacitor polarity. This eliminates the possibility of errors and guarantees that a user follows instructions from the manufacturer.

Multimeter Testing

Experienced engineers can use a multimeter to confirm the polarity of capacitors, particularly when other methods are inconclusive.

- Using a Multimeter: To test capacitor polarity with a multimeter, set the multimeter to measure resistance. Place the probes on the capacitor terminals. The multimeter will show a higher resistance reading when the positive probe is on the positive terminal of the capacitor. If the reading is low or the meter beeps (in continuity mode), the probes are likely reversed.

- Precautions and Techniques: When using a multimeter, ensure that the capacitor is discharged before testing to avoid damaging the meter or getting inaccurate readings. Handle the capacitor carefully, and if you’re uncertain about the results, cross-check with other identification methods or consult the datasheet.

By combining these methods, you can accurately identify the polarity of capacitors, ensuring they function correctly in your circuits and prevent potential damage or failures.

Types of Capacitors and Their Polarity

Capacitors come in various types, each with unique characteristics and applications. Understanding the differences between polarized and non-polarized capacitors is essential for their proper use in electronic circuits.

Polarized Capacitors

Polarized capacitors have a specific positive and negative terminal, requiring correct orientation in a circuit.

Here are the main types of polarized capacitors:

1.Electrolytic Capacitors

- Construction: Electrolytic capacitors use an electrolyte to achieve higher capacitance values than other types of capacitors. They consist of an anode made of aluminum foil coated with an oxide layer, which acts as the dielectric, and a cathode made of a liquid or gel electrolyte.

- Applications: Commonly used in power supply circuits, filtering applications, and coupling/decoupling tasks due to their large capacitance values.

- Polarity Identification: They are marked with a “+” symbol for the positive terminal or a stripe indicating the negative terminal. The longer leg also signifies the positive terminal.

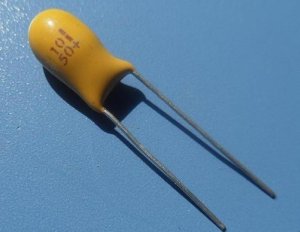

2.Tantalum Capacitors

- Construction: These capacitors have an anode made of tantalum metal and a dielectric layer of tantalum oxide. The cathode is usually a solid or liquid electrolyte.

- Applications: Used in applications requiring stable and reliable performance, such as in military, medical, and automotive electronics.

- Polarity Identification: Tantalum capacitors often have a stripe or a “+” sign to denote the positive terminal. Reversing polarity can lead to catastrophic failure, so correct orientation is crucial.

3.Aluminum Electrolytic Capacitors

- Construction: Similar to standard electrolytic capacitors but specifically use aluminum for the anode and cathode. The dielectric is an oxide layer formed on the aluminum surface.

- Applications: Frequently found in power supplies, audio circuits, and other applications where high capacitance and voltage ratings are needed.

- Polarity Identification: They are marked with a “+” symbol on the positive terminal and sometimes a “-” stripe on the negative terminal. The longer leg indicates the positive terminal.

Non-Polarized Capacitors

Non-polarized capacitors do not have a specific positive or negative terminal, allowing them to be connected in any direction in a circuit. Here are the main types of non-polarized capacitors:

1.Ceramic Capacitors

- Construction: Made from a ceramic material as the dielectric with conductive metal plates on both sides.

- Applications: Widely used in various applications, including filtering, coupling/decoupling, and timing circuits, due to their small size and stability.

- Polarity Identification: Ceramic capacitors do not have polarity markings as they are non-polarized and can be installed in any orientation.

Additional Tips to Deal with Capacitor Polarity in PCBs

When working with capacitors on printed circuit boards, ensuring you handle polarity correctly is crucial for smooth operation.

Here are some straightforward tips to help you manage capacitor polarity effectively:

- Check Polarity Markings

Before soldering, always double-check the markings on both the capacitor and the PCB. Look for symbols like “+” and “-” that show which terminal is positive and which is negative. This visual check prevents mistakes that could damage your circuit.

- Use Polarized Capacitors Wisely

Only use polarized capacitors, such as electrolytic or tantalum types, where needed. Non-polarized capacitors, like ceramics, can be used in any direction without polarity concerns.

- Orient Capacitors Correctly

Follow the PCB markings and design guidelines when placing polarized capacitors. The longer lead usually indicates the positive terminal. Take care during manual soldering or automated assembly to avoid accidentally reversing them.

- Use Design Aids

Take advantage of silkscreen markings, polarity indicators, and PCB layout guides to help you position capacitors accurately. Clear visual cues make assembly easier and reduce the chance of polarity errors.

- Refer to Datasheets

Always consult the capacitor datasheets for detailed polarity instructions, soldering tips, and handling precautions. Datasheets provide essential information to ensure your capacitors perform reliably.

- Perform Quality Checks

After assembly, verify capacitor polarity using a multimeter set to measure resistance or continuity. This step confirms correct connections and catches any polarity issues early.

Conclusion

In conclusion, knowing about capacitor polarity is essential for electronics enthusiasts. Whether you are new or experienced, correctly using polarized capacitors prevents circuit issues.

Always check markings before soldering, use datasheets for guidance, and verify installations. These steps ensure your electronics work reliably and safely. Capacitors are critical components in electronics, and handling them correctly ensures they do their job well.