Wondering what a PCB relay is? If you are getting into electronics, then likely one crucial part is going to confuse you: relays. Relays control circuits and thus often form the most essential part of many projects.

Don’t worry, you’re not alone. In this article, everything you need to know about PCB relays will be explained using simple terms for better understanding.

By the end, you’ll understand how they work, the different types, and how to pick the correct one to meet your needs.

So, let’s get started.

What is PCB Relay

Relays are electrical-controlled switches that open and close the contacts to control the current flow through a circuit. They work by allowing or blocking the current flow, respectively, by opening and closing contacts if they are either energized or de-energized. They, therefore, become indispensable in any application that calls for control and automation.

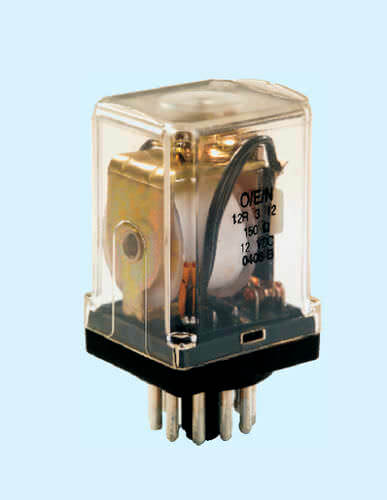

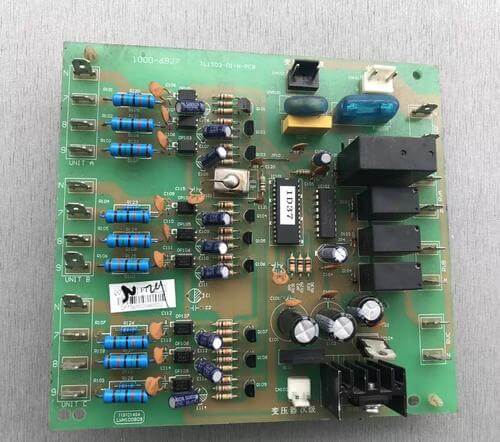

PCB relay has been designed to be mounted on printed circuit boards. PCB relays are compact, easily mounted in an electronic circuit, and are, therefore, very common in modern electronic appliances. They come in different forms, which are suitable for a given application and requirement.

Types of PCB Relays

Different applications use different types of PCB relays. Some of the most common are:

Electromechanical Relays (EMR)

Among relays, electromechanical relays belong to the most common types of PCB relays. They work by the use of a coil that activates a physical switch, and thus, they apply to high currents. On the other hand, they can be slow and have a limited life span because of that fact.

Solid State Relays (SSR)

In solid-state relays, electronic elements serve as the switching elements, in contrast to mechanical components in electromechanical relays.

These have given way to being faster in switching, having a longer life, and being able to change entirely in silence. More often than not, they have a lower current capacity and will be more expensive than electromechanical relays.

Hybrid Relays

Hybrid relays provide a balance of the characteristics of both electromechanical and solid-state relays. This balance includes versatility in current handling, switching speed, and cost from low to high power.

Understanding Relay Operation

Understanding how exactly relays work is crucial for choosing the right one for a particular application. Naturally, both electromechanical and solid-state relays are distinct in mechanisms and carry advantages and suitability for deployment in various situations.

Now let’s discuss the functionality of each type to better understand their role in controlling circuits.

Electromechanical Relays (EMR)

In a typical electromechanical relay, there are three essential functional parts: the coil, the armature, and the contact points. Input applied through the coil will create or close a magnetic field so the armature is either pulled or pushed by magnetic attraction.

According to the relay’s form of operation, it either opens or closes the contact points.

After the input has been removed, the coil releases the magnetic field yields, and the armature is forced back to a usual position that opens or closes the contacts. This is a mechanical action which enables the EMR to control current flow in a circuit.

Solid State Relays (SSR)

Solid state relays realize switching without physical contacts and, instead, use the electronic devices within the unit, such as optocouplers. An optocoupler is such an electronic device that combines light-emitting diodes with photosensitive components.

When light is emitted upon receiving an activation input signal from the light-emitting diode, the photosensitive device perceives such light and allows a switching mechanism for the flow of current to be opened within the solid state relay.

SSRs, in contrast to EMRs, have no moving parts; thus, they work in silence and have a much higher life operation expectancy.

Now you know the basics of PCB relay, it’s time to learn how you can choose the right PCB relay.

Choosing the Right PCB Relay

Selecting the appropriate PCB relay involves considering several key factors to ensure it meets your specific needs:

- Switching Parameters

In selecting a PCB relay size, a few primary considerations come into play regarding switching parameters. This is inclusive of contact rating, which indicates the maximum current and voltage that the relay can operate under.

It implies that, by selecting a relay that has the correct contact rating, one is bound to be assured that the relay sustains the electrical load without any notion of failure.

Additionally, the coil voltage is crucial, as it indicates the voltage required to energize the relay coil. Understanding the power consumption of the relay is also important, as it affects the overall efficiency of your circuit and power budget.

- Performance Considerations

Performance factors are critical in determining the suitability of a relay for your application. Switching speed, for example, is essential if your application requires rapid on-off cycles.

Isolation between the control circuit and the switched circuit is another key factor, providing safety and preventing interference.

For electromechanical relays (EMRs), bounce time— the time it takes for the contacts to settle after switching—can impact the performance and reliability of the circuit, so it’s important to consider this aspect as well.

- Environmental Factors

The operating environment is one of the most critical factors in choosing a PCB relay. The relays have to be selected to operate correctly and to maintain performance and life under continuous exposure at the specified temperature level of the device in which they are utilized.

If vibration or mechanical shock is built into the environment, the relay needs to have a good set of vibration resistance characteristics to avoid the degradation of both performance and life.

Choosing a relay meeting specific environmental specifications will thus guarantee reliable operation without the threat of possible failure.

- Packaging and Mounting

The other important design area is the physical design of the relay, together with the mounting. You will place the relay with either through-hole mounting, due to the need for securing, or surface-mounted devices, since they are always compact and fit with a high-density circuit board.

The footprint size will have to be in line with the available space on the PCB, assuring a perfect fit and the functioning of the part.

For applications where a high level of power is being handled, relays with built-in heat sinks might help take care of heating problems without compromising performance.

- Cost Considerations

In addition, cost is the critical point when making the proper choice for a PCB relay. High-performing relays may contain high-end features to offer, but they have a much steeper price.

Balancing the features and performance required with budgetary constraints is crucial in getting the best value for your money. After all, one has to select such a relay which can reach its performance level according to the given application but not exceed one’s target for the relay—as it rises to efficiency and cost-effectiveness.

Applications of PCB Relays

PCB relays are versatile components used in a wide range of electronic systems.

Here are some common applications:

- Power Supplies

PCB relays control the switching of power supplies, turning on and off, controlling different types of outputs, and power distribution. They assist in maintaining the flow of power for devices in their system to ensure that they get the appropriate voltage and current.

This allows power from a surge to sensitive electronic parts and also for the effectiveness in ensuring that power reaches the operation for the power supply system.

- Motor Control Systems

PCB relays play a significant role in motor control systems. They are used to start, stop, and reverse motors, providing precise control over motor operation. This application is essential in industrial automation, where motors drive various machinery and equipment. The reliability and efficiency of PCB relays make them ideal for controlling motor functions and ensuring smooth operation.

- Security Alarm Systems

Applications for PCB relays are in security alarm systems, which provide system alertness according to input signals from various sensors. With sensor input indicating an intrusion or any other security breach, the relay will trigger the alarm to alert the security system or the personnel.

It is critically important that this should be a rapid and reliable reaction to maintain the security of the property.

- Data Acquisition Systems

Typically, in data acquisition systems, PCB relays are essential to route signals for measurement effectively. In other words, they switch the different signal paths, which enables the system to pull data from different sensors and input points.

For the system to accurately collect and analyze data, the following must facilitate its very functioning: environmental monitoring, industrial process control, and scientific research.

- Internet of Things (IoT) Devices

PCB relays bring about the actuation of end devices and interfacing with sensors in the burgeoning IoT fast lane. They make the physical world receptive to these IoT devices, which enable anything that acquires data to guide actions.

For example, a relay can switch on a light, open a valve, or set a motor running according to sensor inputs, thus endowing IoT-enabled devices with new functionality not seen before.

PCB relays are essential in these and many other technologies to provide reliable and efficient control in electronic circuits. Their versatility and performance make them one of the building blocks of today’s technologies.

Troubleshooting PCB Relay Issues

Here are some practical tips that will help you troubleshoot and fix PCB relay issues:

1.Relay Not Switching

If a PCB relay is unable to operate the switching function, the first thing to check is the coil voltage. Ensure that the relay receives the applied voltage for activating the coil.

Observe the relay connections to make sure those are tight, and there are no wires that are loose or damaged. Check the continuity of the relay regarding verification of the integrity of the components and the state of good work.

2.Arcing or Contact Bounce (EMRs)

This contact bounce or arcing in the electromechanical relays can create unreliability concerns. This effect is countered by using snubber circuits, which drop down the voltage spikes and, hence, bring down the phenomenon of arcing over the relay contacts.

However, you can equally well opt for higher-rated relays that will handle the operation without arcing or bouncing.

3.Overheating

If the PCB relay overheats during operation, it may indicate inadequate heat dissipation or improper relay selection for the current load. Ensure that the relay is mounted on a heat sink if necessary, to enhance heat dissipation and prevent overheating.

Verify that the relay selected matches the current load requirements of the application. Choosing a relay with a higher current rating can also help prevent overheating issues.

Final Words

Taking all these together, PCB relays are indeed vital to any kind of electronics because they not only control the flow of current but also automate tasks in the allocated applications. PCB relays guarantee precise control and 100% reliable power to IoT exposure devices.

These insights empower electronics users to make the most of PCB relays in their projects and applications, enhancing efficiency and functionality.