Are you wondering what is FPT and why does it matter? If you’ve ever worked with PCB assemblies, implementing proper operation can be more than a challenge.

But don’t worry because here in this article, we are going to discuss everything you need to know about FPT including what it is, how does it work, the benefits, limitations, etc. By the time you are done reading this, you will get a clear idea if FPT is the right solution for any of your testing needs.

Well, let’s begin.

What is Flying Probe Testing - FPT

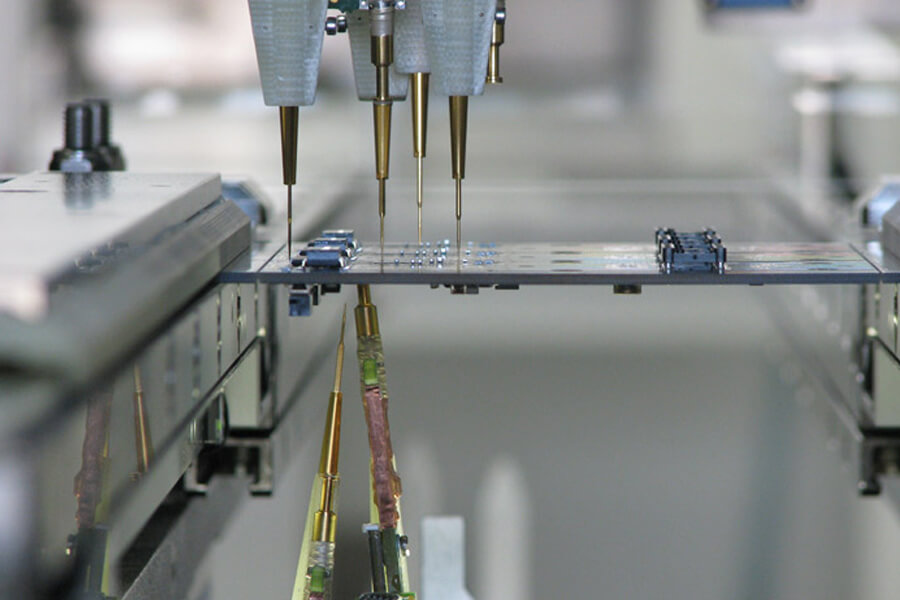

FPT is a higher-end testing technique that greatly advances testing for Printed Circuit Boards and does not rely on costly test fixtures. Unlike the conventional ICT, which uses a specially designed fixture for the test of every board design, FPT uses movable ICT probes that are software-driven for executing a test at nearly all points on a PCBA.

The flexibility of FPT makes it the best policy in place for product testing purposes with small productions, prototypes, and PCBs of complex design.

How Flying Probe Testing Works

Here’s how Flying Probe Testing works:

1.Probes Move Around:

The system has several probes, between four and eight, implemented on robotic hands. These probes scout over the entire PCD, sweeping the points through which pads, vias, and components run.

2.Testing Process:

The probes transfer the signals to the PCB and either measure voltage, resistance, or the continuity of the circuits. The system will then compare the readings to what they should be to locate the problems.

3.Software Controls the Process:

The software used also controls the movements of the probes to set locations for testing. The software has the PCB design programming to specific detail, and hence testing is accurate and with high efficiency.

4.No Custom Fixtures Needed:

Any point on the PCB can be defined as a touch location, which means no custom design of the test fixtures is necessary. These save time and money, converting FPT into wasteful emission measures that are delicious for many prototypes or small batch tests.

5.Finding Defects:

FPT can trace the faults because of open circuits, short circuits, and components’ improper placement. Test results are recorded and analyzed for further improvements.

6.Easy to Adapt:

It can be easily catered for various designs of a PCB by a fast and easy upgrade of software. This makes the testing of new designs simple without alteration in the hardware.

Flying Probe Machine Components

An FPT machine typically consists of several essential components:

- Probes:Needles will make physical contact with the PCB at specially designated test points.

- Test Fixture: Although FPT does not require a custom fixture for every board, it will still utilize a fixture for holding the PCB in place during the testing.

- Test Program Generator: A program that outputs a set of instructions that can direct the probes in order to test the right points in the PCB.

Advantages of Flying Probe Testing (FPT)

Here are some advantages of FPT that you must know:

- Flexibility and Adaptability

One of the greatest advantages of FPT is that it can adapt to virtually any PCB design because it does not require a customized fixture. This makes it ideal for testing prototypes or small production runs, when creating a new fixture for every design would be impractical.

- High-Speed Testing

FPT also characterizes speed. Probes move fast across the board, testing several points within a very short period. This high-speed testing capability helps in time-critical projects and guarantees efficient testing of very complex PCBs.

- Reduced Fixture Costs

Traditional ICT can be costly due to the need for custom fixtures, and with FPT, this cost is eliminated, making FPT a much more cost-effective approach for low volume, or the testing of a prototype.

- Ability to Test Complex PCBs

FPT is recommended for testing dense and complex PCBs that have extremely tight pitches. The probes can land in small and uneven irregularly shaped areas that are undefineable otherwise.

Limitations of Flying Probe Testing (FPT)

Besides advantages, there are some disadvantages that you must know:

- Potential for Damage to PCBs

While in general, FPT is safe, there is a limited potential to harm the PCB under the test. The probes make contact physically with the board, which can cause scratches or other small physical damage.

- Limitations in Testing Certain Component Types

Flying probes are an ineffective way of testing components, especially those of very fine pitch and those with delicate leads, in the case a failure occurs.

- Accuracy and Precision Considerations

As you probably can understand, FPT is really pinpoint-reliable, but it will not always give the same precision that a dedicated ICT fixture will provide. This is especially true when very small or tightly packed components under test are spawned.

Applications of FPT

The major applications of FPT include:

1.PCB Prototyping

FPT is used in the prototype phase of PCB development. It is suitable for testing before engaging a company in full production due to its flexibility and adaptability while trying out designs.

2.Production Testing

Besides prototyping, FPT also accommodates FPT production testing. Mostly, this FPT is applied during the low to medium runs. It is an effective and economical process to give assurance to the end product of the PCB before they are dispatched to the consumers.

Conclusion

In conclusion, FPT is flexible, low-cost, and hassle-free in nature for numerous designs of PCBs. Be it a prototype or a production board, FPT offers a way to achieve adaptiveness and correctness in the being and assures dependable results.