You probably find yourself wondering what a printed circuit board is and what it actually does. Don’t worry though; you are not alone. Many people feel the same way upon hearing such technical terms.

Never mind, as we are going to explain everything to you. In this article, we will discuss everything about PCBs including what they are, what they do, key functions, components, benefits, applications, etc.

Let’s get started.

What is a Printed Circuit Board

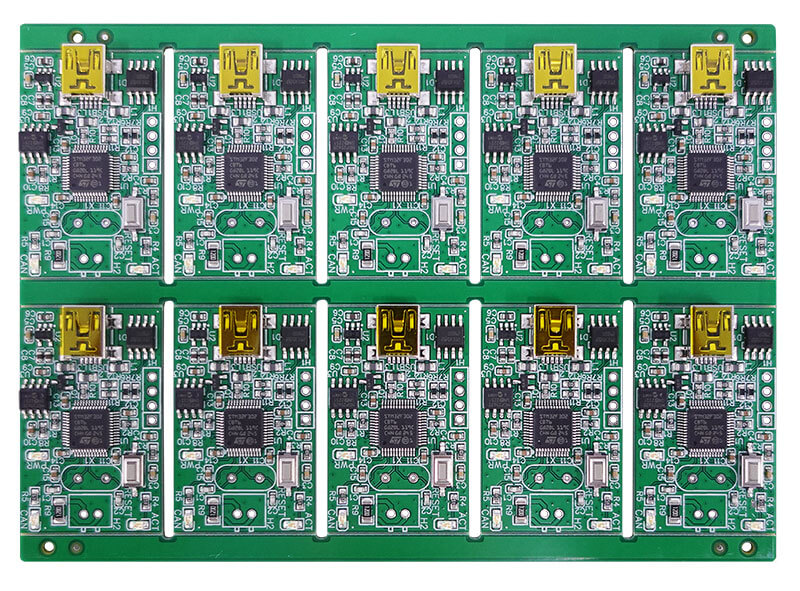

Well, a Printed Circuit Board, or PCB, is the basic building block of electronics used in every electronic gadget. In a general sense, it is a thin board made out of fiberglass, a composite epoxy, or some other insulating material, upon which electronic components are mounted.

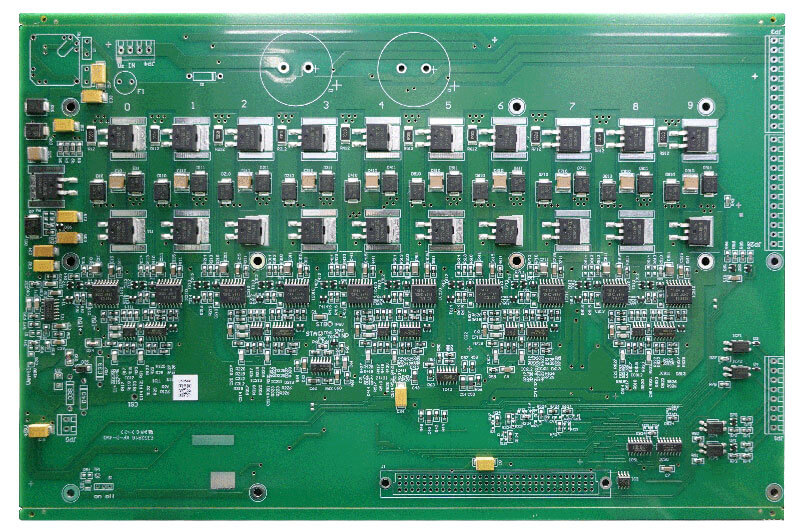

A PCB has a very complex design on its surface, with conductive tracks, pads, and just about any other metallic feature, etched from copper sheets laminated onto the substrate.

Electronic components, such as resistors, capacitors, and integrated circuits, are then soldered onto the PCB, establishing a reliable and streamlined method of electrical connection and interaction between the components.

This innovation has taken the designing and manufacturing of electronics to a whole new level with enabling them to be more functional yet compact and efficient in the designing of these components.

Now let’s discuss some key functions of a PCB in detail.

The Key Functions of a PCB

As said above, Printed Circuit Boards serve as the backbone in electronic devices.

Here are some key functions of a PCB that you must know:

1.Structured Component Layout

PCBs allow for the structuring of electronic components in an organized and ordered manner. The layout effectively positions every component to affect decent electrical connections, effective thermal management, and functionality in a device.

2.Miniaturization of Electronic Devices

PCBs help to miniaturize electronic devices by attaching components onto a flat board with the least amount of hassle.

They allow advances in packing large numbers of components into small planes by manufacturers to produce smaller, more compact electronic gadgets. These become essentials for things like consumer electronics where often compact size is a primary design requirement.

3.Reliable Electrical Connections

Besides, a PCB is intended to provide consistent and reliable connectivity through electrical connections that are linked from one device to another.

Conductive traces, vias, and pads are employed in the PCB to ensure that electrical signals transition from one part to another with minimal interference in other parts of the circuit and with least likelihood of loss in connectivity.

The fact of reliability presents itself as one of the key issues in assuring proper operation of electronic devices for numerous applications, from consumer electronics to aerospace systems.

Besides, PCBs do much more than this; they facilitate the manufacturing, troubleshooting, and repair work of an electronic gadget. So PCBs have become a valuable part in present-day electronics.

But you must be wondering how PCBs are able to do all these things? What are the components behind the wonders of PCB? Let’s discuss this below.

Components of a PCB

A PCB comprises several essential components that contribute to its functionality:

- Conductive Tracks

These are thin lines of copper that are etched onto the surface of the PCB. They act as electric pathways on the board in which a current may flow to reach other components on the board.

Conductive tracks are typically created through a process of copper etching, where unwanted copper is removed from the board, leaving behind the desired pattern of conductive pathways.

- Pads

Pads are small round metal areas on the board that electronic components are soldered to. They ensure stability and good contact between the component and the conductive tracks in a PCB.

Usually, pads are provided in differing shapes and sizes corresponding to either the type or size of the component to be soldered.

- Vias

Vias are small holes drilled into the surface of a PCB and then plated with metal to connect the different layers within multilayer designs. In fact, they work as if they were vertical interconnections, allowing conductive tracks on different layers to be connected to each other.

This makes them particularly useful for dense and complex PCB designs in which a lot of components need interface connections.

Now that you have some of the basics of PCBs, let’s find out the advantages in modern electronics.

Benefits of Using PCBs

Some advantages of using PCBs among the other methods in modern electronic appliances are:

- Improved Reliability

PCBs are much less likely to have problems with loose wires or bad connections, when compared to a circuit made with point-to-point or wire wrap wiring techniques.

The track connections are all soldered and pinned out in a set pattern. PCBs offer a level of stability and reliability to electrical connections that alleviate poorly placed connections.

- Miniaturization

PCBs can support compact designs. With the elimination of bulky wiring systems and having been replaced by intricately designed conductive tracks to make complete utilization of space.

The circuit boards ensured that more components could further be packed in the vicinity or closer to one another, thus making gadgets sleeker and more portable.

- Mass Production

PCBs facilitate automated assembly processes, making mass production of electronic devices more efficient and cost-effective.

Machines can place the parts on the PCB in an exact way, solder them in their places, and check for quality to guarantee a similar kind of quality, thus saving production time.

- Performance

Further, PCBs improve signal integrity and therefore contribute to the overall performance of a circuit.

The proper design of conductive tracks and optimum reduction of electromagnetic inference ensure that the quality of signals is high with better performance and reliability of devices.

- Ease of Troubleshooting and Maintenance

PCBs support troubleshooting and maintenance procedures to a far greater extent than what the conventional wiring structures can do.

Because they come with structured layouts and clearly defined connections, technicians can easily identify and remedy problems, thereby offsetting downtime and keeping repair costs at the lowest.

- Flexibility in Design

The PCBs provide maximum flexibility of circuit design to the designer. It becomes very easy to reorganize components and alter circuit configuration with minor rewiring.

This gives flexibility to modification in design to enchase performance along with customization with respect to a specific function.

- Environmental Considerations

The PCBs promote environmental conservation in terms of the minimization in material wastage and energy consumption. Compared to point-to-point wiring, which often requires more materials and labor, PCBs streamline the manufacturing process, resulting in fewer resources expended and less waste generated.

Additionally, PCBs can be recycled at the end of their lifecycle, further reducing environmental impact.

Applications of PCBs

PCBs are used in many electronics applications and devices.

1.Smartphones and Computers:

PCBs represent the basic building block for smartphones, computers, and all other portable gadgets. They provide a base for complicated circuitry that follows commands from such devices to work in conjunction with each other, allowing great features.

2.TVs and Other Consumer Electronics:

In the realm of consumer electronics, PCBs are ubiquitous. They serve as the backbone of televisions, home entertainment systems, gaming consoles, and various household appliances, enabling these devices to perform their intended functions reliably and efficiently.

3.Industrial Control Systems:

PCBs are extremely critical in terms of industrial control systems since precision and reliability are the two key factors.

Programmable logic controllers, motor control systems, sensors, and other automation systems make the process fully functional and yield manufacturing plants and industrial facilities in perfect order with precise control.

4.Medical Devices and Instruments:

PCBs form a very strong component of any medical device or diagnostic, monitoring, and treatment tool.

From ultrasound machines to MRI scanners, from pacemakers to infusion pumps, PCBs make possible harmonizing of electronic parts while the accuracy and credibility of the medical equipment are assured.

5.Automotive Electronics:

The application of PCBs in automobiles can vary across a wide array of uses, from engine control units (ECUs), infotainment, and navigation to safety features such as airbag control modules and anti-lock braking systems (ABS).

PCBs in automobiles must meet stringent reliability and durability standards to withstand harsh operating conditions.

So, PCBs are versatile components that underpin the functionality of countless electronic devices, spanning industries from consumer electronics to healthcare and beyond.

Their widespread adoption underlines their very important role in driving technological innovation and progress.

Conclusion

In conclusion, printed circuit boards are the unsung heroes of modern electronics; they have revolutionized the way electronic devices can be designed, manufactured, and operated.

By getting to the basics of PCBs, one would understand what the key functions, components, benefits, and applications are that lend to understanding how important and versatile they are in driving many electronic devices upon which we tend to rely every day.

So, the next time you use your smartphone, switch on your TV, or drive your car, just be grateful for all the technology in the background and for how it is being made possible, thanks to the wonderful Printed Circuit Board.