Turnkey PCB assembly is a full-service solution that simplifies the entire process of printed circuit board production, from sourcing components to final delivery. This model of PCB assembly has become increasingly popular due to its cost-effective nature and the convenience it offers by streamlining multiple production stages into a single, efficient workflow. Whether you’re seeking a complete assembly solution or just parts of it, turnkey services offer a versatile approach to manufacturing.

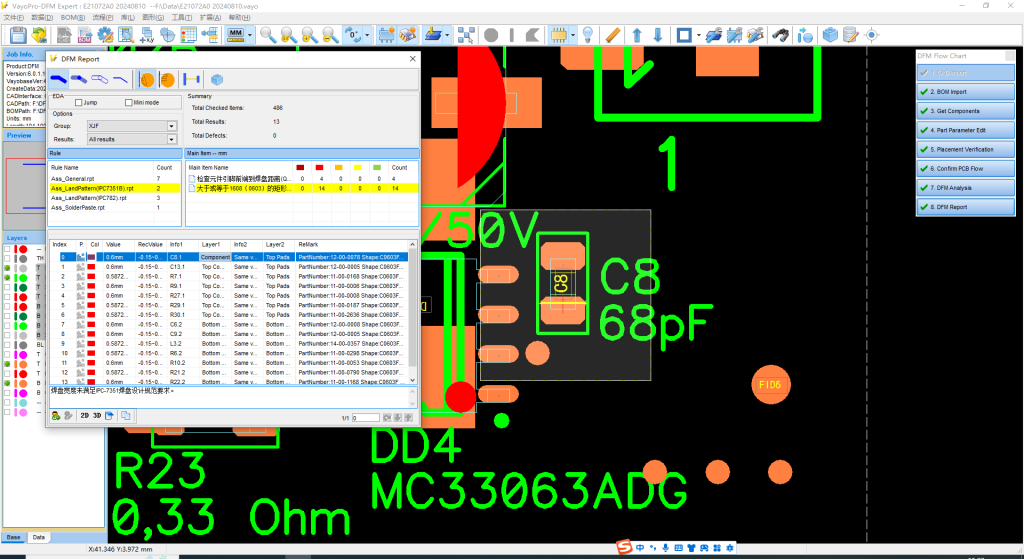

At KEEP BEST, we offer not only turnkey PCB assembly but also a free DFM (Design for Manufacturability) service to help optimize designs before production, ensuring efficiency and minimizing errors. Additionally, our Thailand-based factory enables us to provide competitive pricing and shorter lead times for our customers around the globe.

What is Turnkey PCB Assembly?

In essence, turnkey PCB assembly is an all-inclusive manufacturing process. It covers every step, from procuring components and managing the bill of materials (BOM) to assembling, testing, and delivering the finished product. Turnkey providers take full responsibility for the supply chain, including selecting components, ensuring RoHS compliance, and conducting rigorous quality control measures. This holistic approach minimizes the involvement of multiple suppliers, reducing potential errors and ensuring faster production timelines.

Types of Turnkey Services

There are two primary types of turnkey services: full turnkey and partial turnkey.

Full Turnkey PCB Assembly: In a full turnkey solution, the manufacturer handles every aspect of the production process. This includes sourcing the components, assembling the PCB, performing testing, and delivering the finished boards. Full turnkey services are ideal for companies looking for a hands-off approach, as the turnkey provider manages the entire supply chain and assembly process.

Partial Turnkey PCB Assembly: In a partial turnkey solution, the manufacturer takes responsibility for only part of the assembly process. For example, a company may provide the BOM and certain specialized components, while the turnkey provider handles assembly, soldering, and testing. This option is useful when companies want more control over specific elements of production while still benefiting from the turnkey provider’s expertise in assembly and testing.

Benefits of Turnkey PCB Assembly

Turnkey PCB assembly offers numerous advantages, particularly in terms of efficiency, cost-effectiveness, and quality. Here are some key benefits:

1. Efficiency and Shorter Lead Times

One of the main reasons companies choose turnkey assembly is its ability to significantly reduce lead times. By consolidating all the production stages under one roof, turnkey providers streamline processes, cutting down on delays caused by coordinating multiple suppliers or production facilities. With KEEP BEST’s Thailand-based factory, we ensure fast production cycles that meet global demand efficiently.

2. Cost-Effectiveness

Turnkey PCB assembly can be highly cost-effective. By leveraging their relationships with suppliers, turnkey providers often obtain components at lower costs, which translates into savings for the client. Additionally, managing all aspects of production internally reduces administrative and logistical expenses, further contributing to a more economical solution. Our free DFM service ensures that your designs are optimized early in the process, saving both time and money by minimizing potential issues before production begins.

3. Reduced Errors

Working with a single turnkey provider helps reduce errors, especially when it comes to component procurement and assembly. With the entire process managed in-house, there is less risk of miscommunication between different parties. Quality control is also more consistent, as turnkey providers typically conduct thorough testing at each stage of production to ensure that every board meets the required standards.

4. Customization and Flexibility

Turnkey services offer a high level of customization to meet specific project needs. Providers can tailor their services to accommodate specialized components, unique design requirements, or strict regulatory standards like RoHS compliance. For example, a turnkey provider can handle complex box builds or other custom assembly requirements, ensuring that the final product is ready for integration into a larger system.

5. Rigorous Quality Control

One of the standout advantages of turnkey PCB assembly is the rigorous quality control processes in place. Turnkey providers typically offer end-to-end testing services, ensuring that every board is thoroughly inspected before delivery. This includes functional testing, automated optical inspection (AOI), and X-ray inspection for complex assemblies such as those involving BGA components. Consistent testing throughout the assembly process helps identify and resolve any potential issues early, reducing the likelihood of costly rework or product failures.

Choosing the Right Turnkey Solution

When selecting a turnkey PCB assembly provider, it’s essential to evaluate your project’s specific needs. If you require a fully managed service that includes component sourcing, assembly, and testing, a full turnkey solution is likely the best option. However, if you prefer to retain control over certain aspects of the production process—such as providing your own components or managing part of the testing—a partial turnkey solution may be more appropriate.

In either case, ensure the provider has strong quality control protocols and can meet your regulatory requirements, whether that’s ensuring RoHS compliance or adhering to industry-specific standards. It’s also important to choose a provider with experience in box build and other complex assembly tasks if your project requires them.

Conclusion

Turnkey PCB assembly offers a streamlined, cost-effective solution for companies looking to simplify their production processes. By managing every stage of the assembly—from component procurement to testing and delivery—turnkey providers help reduce lead times, minimize errors, and ensure consistent quality control. Whether you need a full turnkey service or a more flexible partial turnkey option, these solutions can be tailored to meet your specific project needs.

At KEEP BEST, we take pride in offering comprehensive solutions with our free DFM service and a state-of-the-art Thailand-based factory, enabling us to provide fast, reliable, and cost-efficient PCB assembly to customers worldwide.