Are you tired of dealing with PCB design issues that compromise your project’s performance? You are not alone as many engineers face challenges with PCB design quality, leading to frustrating setbacks and costly errors.

But do not worry, as this comprehensive guide will help you explore common pitfalls and practical solutions in a way that your quality of PCB design does not suffer.

From understanding key indices to dealing with standards and specifications, jointly we will discuss everything. By the end, you will have both knowledge and instruments that will help confidently assess, improve, and maintain your PCB quality and design.

So, let’s get started.

PCB Design Quality Overview

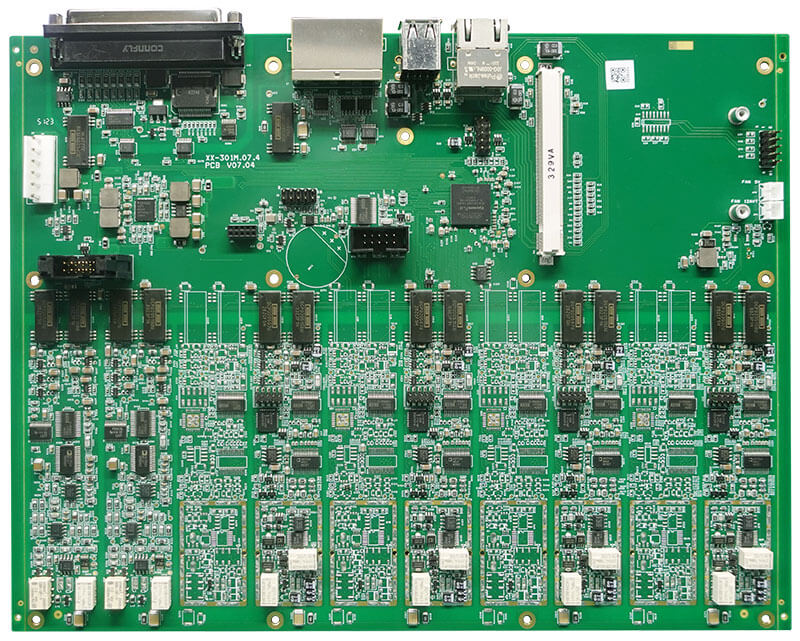

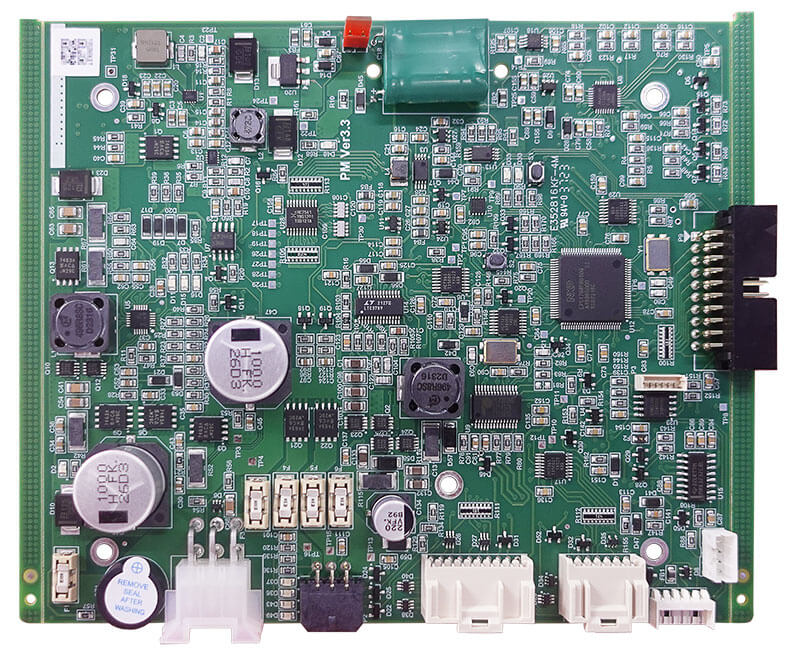

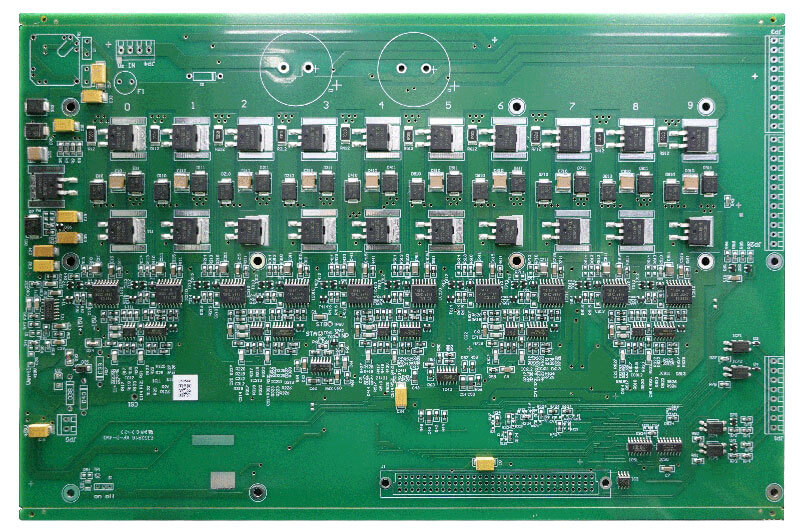

Well, the PCB design quality refers not only to producing a well-functioning layout of a circuit but refers to a design that performs in a reliable manner over a scope of conditions, adherence to industry standards, and manufacturability at low cost.

It is efficiently intended by factors like layout, signal integrity, thermal management, manufacturability, and reliability of the design concerned.

To achieve optimal PCB design quality, it’s essential to first understand the PCB design quality indicators.

Let’s discuss them in detail below.

PCB Design Quality Indicators

As said above, understanding these in all its indices is essential for the creation of a robust and reliable circuit board.

These indicators serve as benchmarks for evaluating the performance, manufacturability, and reliability of a design.

Here are some key indicators to consider:

- Quality of signal: Make sure there is no strength or clarity of the signal being lost as it crosses the board. Watch out for such items as signal distortion, or any type of noise that might be confusing your signals.

- Distribution of power: See how the power flows through the board. You want it to flow evenly, without large steps down, interfacing with other parts of the board, or, as an example, around soldering pads. Look for things like voltage regulation or how well you have connected your power parts.

- Heat Control: You should never allow your board to be too hot. Otherwise, if it does, it can risk the breakdown of some components. Ensure that heated parts do not get too hot. You can use some special tools to help you in the decision.

- Easy to Manufacture: Your design should be easy for the manufacturers to build. If it’s complicated, then chances are high for them to make many mistakes. Ensure that your design follows guidelines and that the parts included are easy to assemble.

- Reliability: Lastly, make sure your board will keep working for a long time. You don’t want it to break down quickly. Check if it meets reliability standards and if it can handle tough conditions.

Besides these indicators, there are some standards and specifications of a good PCB design quality that you must know.

Standards and Specifications Related to PCB Design Quality

Knowing about certain rules and guidelines can really help make sure your PCB design is top-notch.

Here are some simple standards and specifications you should keep in mind:

1.IPC Standards:

The Institute for Printed Circuits (IPC) has placed down some rules in regards to the design of PCBs. One very important one is IPC-2221, which describes how to design good PCBs, e.g., what material to use and how to lay things out.

2.IPC-A-600:

IPC-A-600 is a rulebook that indicates directly the way good bare PCB shall look. It talks about things like how wide tracks shall be or how big the holes may be. Adhering to IPC-A-600 automatically means defect-free boards.

3.IPC-6012:

This tells you how to make rigid PCBs that work well. It tells about the material choice, how to put everything together, and how to make sure it is good enough. Adhering to the instructions herein would ensure the reliability of your PCBs.

4.IEEE Standards:

Another group, the Institute of Electrical and Electronics Engineers (IEEE), has its standards. For example, IEEE 802.3 introduces a standard describing how to configure an Ethernet network, including the data on PCB design operating at increased speeds.

5.Military Standards (MIL-STD):

Working in the aerospace industry requires adherence to military standards. Take MIL-PRF-31032, for example, which gives a description of how to make PCBs that can take tough conditions.

By sticking to these simple rules, you can make sure your PCB designs meet quality standards and work reliably.

Now you know the basics of PCB design quality, it’s time to learn how you can judge a PCB design quality.

How to Judge PCB Design Quality?

Here are some simple ways to judge the quality of a PCB design:

1.Look at efficiency in Layout:

Take a look at how well components are arranged on the board. A well-organized layout minimizes signal interference and makes the board easier to manufacture and assemble.

2.Integrity of Signal:

It tests on the integrity of the signal if it is able to retain its quality when moving through the tracks. Good signal integrity should have low distortion, low noise, and appropriate impedance matching.

3.Placement:

While considering placement for board components, ideal placement takes into consideration signals paths, thermal management, and manufacturability.

4.Thermal Management:

Look at how the design deals with heat. Good thermal management ensures that components do not run into temperature safety limits and hence avoid overheating, leading to premature failure of what it is expected to.

5.Manufacturability:

How easy is it to manufacture the proposed design? The manufacturability of this design may conform to DFM guidelines and could take into consideration manufacturing constraints implementable without errors.

6.Reliability Features:

Look for reliability features like redundant connections, good grounding, and heavy traces.

All these factors, when considered, are those helping you to come at good judgment about the quality of PCB design.

A good-quality design will work perfectly and will be such that not only keeps the manufacturing cost at a minimum but also ensures that it remains long-term reliable.

But you must be wondering what are the factors that affect PCB design quality. Let’s discuss this in detail.

Factors Affecting PCB Design Quality

Well, there are differnet factors that affect a PCB design quality. The most important ones are:

1.Component Selection:

The choice of components significantly impacts the performance, reliability, and manufacturability of a PCB design.

Selecting high-quality components that meet the project’s requirements is crucial for ensuring optimal performance and longevity.

2.Layout Consideration:

The way the components are placed over the PCB can have an impact not only on signal integrity but also on thermal management and manufacturability.

3.Signal Integrity:

Signal integrity is of great importance in the sense that the signal has got to maintain integrity passing through the PCB at all costs.

The trace impedance, routing topology, and ground plane design are some of the factors that might influence the same signal integrity, to be handled with a lot of caution in the design.

4.Thermal Management:

The major field that protects components from overheating and guarantees the long life of the components is effective heat dissipation.

All these are contributing factors in thermal management for design in PCB: thermal vias, heatsinks, and proper placement of components.

5.Manufacturability:

Design for manufacturability (DFM) of a PCB design is important so that it takes manufacturability into consideration while designing, making sure that the product is defect-free and can be manufactured easily and efficiently assembled.

They are affecting, in turn, the ease of manufacturing and assembly.

6.Environmental Considerations:

The following need to be taken into consideration during the design of special add-ons for installation on the PCB within the operational environment of the PCB: service performance, reliability, temperature, humidity, and vibration.

Methods to Improve PCB Design Quality

Here are some methods and tips that will help you improve your PCB design quality:

1.Design iteration:

Take an iterative design approach, where based on feedback and constant analysis, you keep refining and optimizing the layout. This way, an iterative process can search for potential problems and fix them much earlier than you would if you were using an altogether different approach to design, with much greater chance of getting a high-quality final design.

2.Design for Manufacturing (DFM):

Incorporate DFM principles in your design to ensure your design is manufacturable and a product with fewer errors in the production process. Design with panelization, component placement, solder mask design, and manufacturing tolerances should be done to produce the product in a maximally economical way.

3.Compliance with Standards:

Compliance with industry standards and specifications is one of the prime requisites that assure quality design, facilitating regulatory norms. The factors governing this include mainly IPC standards, IEEE guidelines, and customer specifications.

To these ends, if thought of this way, the design will enable PCB layouts capable of meeting high-quality standards, working with reliability, and suited to the needs of the application at hand.

Conclusion

So that’s all you need to know about PCB design quality. Now you are equipped with a comprehensive understanding of PCB design quality, from identifying indicators to judging quality, understanding influencing factors, and implementing methods for improvement.

So, go forth and create top-notch PCB designs with confidence!