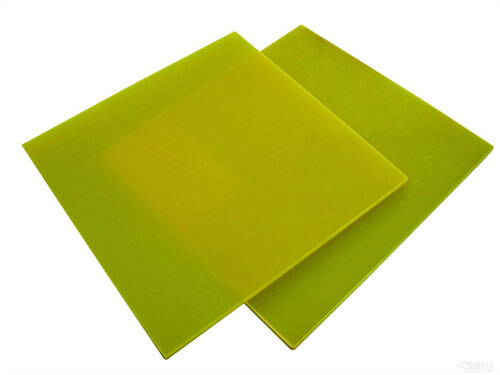

FR-4 Definition

FR-4 is a commonly used PCB substrate made from fiberglass and epoxy resin. It is known for its strength, excellent insulation properties, water resistance, and affordability. The name “FR-4” is actually a grade designation that indicates the material has flame-retardant properties. It is widely used in the circuit boards of electronic devices such as computers and smartphones.

FAQs

Flame Retardant

FR4 is a standard defined by the NEMA (National Electrical Manufacturers Association) for a glass-reinforced epoxy resin laminate. FR stands for “flame retardant” and indicates that the material is compliant with the UL94V-0 standard on plastic material inflammability.

The designation FR-4 was created by NEMA in 1968. FR-4 glass epoxy is a popular and versatile high-pressure thermoset plastic laminate grade with good strength to weight ratios. With near zero water absorption, FR-4 is most commonly used as an electrical insulator possessing considerable mechanical strength.

*Source:https://en.wikipedia.org

Aluminum PCBs are suitable for applications that require high thermal conductivity and electrical conductivity, while FR4 PCBs are suitable for general electronic circuits. Understanding these differences can help engineers and designers make informed choices to meet the needs of their projects.

*Source:ttps://www.pcbway.com

Not Suitable for High-frequency Applications: The circuit board material FR4 dielectric constant changes with frequency and is non-uniform in high-speed, high-frequency applications. Besides, circuit board material FR4 has a higher dissipation factor, resulting in higher signal loss.

*Source:https://www.viasion.com

FR4 sheets are electrical insulators with high dielectric strength. They also feature a high strength-to-weight ratio and are lightweight and resistant to moisture. Add this to their relative temperature resistance, and FR4 material can perform well in most environmental conditions.

*Source:https://www.mclpcb.com

Zero Defect

Quick-turn service

PCBA Manufacture

Learn how Keep Best can turn your designs into products.

Related Articles

External Resources

Related Terms

- No