As you may know, CCL is the backbone of every printed circuit board, but understanding what it is and why it’s important can be tricky. Curious about its types, and properties, or confused about which one to select?

If you feel so, you are not alone. Most people don’t appear to understand copper clad laminates, mainly because they dictate the functionality of most electronic devices. But don’t worry as this guide is here to help you.

From basic structure to the main uses of CCL, we will guide you through all, so you can walk confidently in selecting the right one for your needs.

So let’s get started.

What Is Copper Clad Laminate (CCL)

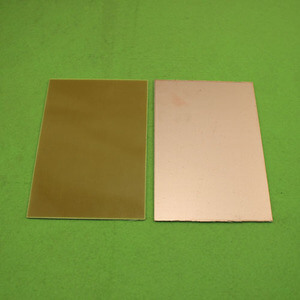

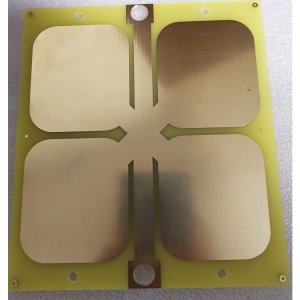

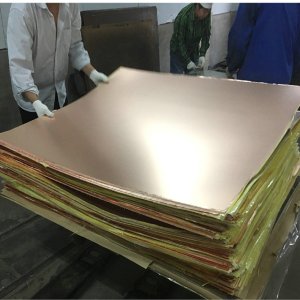

Copper Clad Laminate is a substrate material out of which conductors are patterned to build Printed Circuit Boards. It is mostly made out of fiberglass-reinforced epoxy resin, bonded with thin copper foil on one or, as in new versions, on both sides.

This material is the foundation for creating the conductive pathways in PCBs that allow electronic components to communicate and function effectively.

There are different types of CCL that are used for different PCBs. Let’s discuss them in detail.

Types of Copper Clad Laminate (CCL)

Here are some most important types of CCL:

1.FR4 (Flame Retardant 4)

FR-4 is the most-used CCL in the electronics industry. The reasons for such popularity are its strength and flame resistance, with good insulation. FR-4 includes a woven fiberglass cloth combined with epoxy resin that makes it rigid and durable.

It finds extensive applications in the electronics used in daily life, starting from consumer gadgets to industrial devices, providing firmness and secure service in working environments with high temperatures.

2.CEM-1 (Composite Epoxy Material)

Another type of CCL is CEM-1, mostly used for low-cost, single-layer circuit boards. It is manufactured from paper and glass fiber, mixed and bonded together with an epoxy resin.

It is inefficient compared to FR4; nevertheless, it has proven quite cheap to use in simple electronics, like home appliances. Easily fabricated, it shows good performance for the price when used in simple circuits.

3.High-Frequency Materials (PTFE, Teflon)

High-frequency CCLs are used in those electronic circuits requiring extremely high speeds and frequencies. The lamination used is bound to contain materials such as PTFE, popularly known as Teflon, for their superb ability to reduce signal loss.

They become vital in all RF and telecommunication devices where signal quality needs to be very high. These materials perform very nicely at extremely high temperatures, ensuring reliable performance in different critical circumstances.

4.Flexible and Rigid-Flex Materials

Flexible and rigid-flex CCLs are used in designs where the circuit needs to bend or fit into tight spaces. In the area of application, flexible CCLs are made with the use of polyimide substrates so they can bend without breaking.

Application areas include wearable technology, foldable devices, and compact gadgets in general. The rigid-flex CCLs combine both sections—rigid and flexible—onto one single board; hence, they are perfect where space is constrained and reliability has to be there, as in the case of medical devices, aerospace, or military electronics.

5.Metal Core Laminates

Metal core CCLs are designed for applications in which heat management plays a big role. They are based on a metal layer, usually made of aluminum or copper, which helps in conducting heat away from the circuit.

These types of CCLs are used in applications such as high-power LEDs, automotive electronics, and power supplies due to their nature requiring excess heat, which raises problems.

Such laminates allow a device to operate cooler and more efficiently, thereby extending the device’s life and making it more reliable under high-power conditions.

Now you must be wondering about the CCL construction, which is a ready joke for you.

CCL Construction

Understanding the construction of CCL helps in selecting the right material for your application:

1)Base Material

The base material underpins the first CCL layer. It gives the CCL structural and insulating power. The following materials are laminated as base materials:

- Epoxy Glass (FR-4): It finds wide application due to its good electrical insulation properties and relatively low cost.

- Polyimide: Applications include very demanding uses, high-temperature resistance, and mechanical stability.

- Ceramic: Excellent thermal and electrical properties make these ceramics materials in high demand for high-speed and high-performance-based applications.

2)Copper Foil

Copper foil is used to create the conductive paths in a CCL. The quality and thickness of the copper foil impact the performance of the CCL:

- Thickness: Thicker thicknesses of foil materials lower resistance and result in higher current carrying capabilities but are more expensive and less flexible.

- Surface Treatment: It may be applied to the surface of the copper to give it greater adhesion/bonding with other layers.

3)Bonding Process

The bonding process involves critical requirements to make the layers of CCL accommodate each other very well, so they can perform synergistically. Important bonding processes include:

- Thermal Compression Bonding: Layer bonding is done by applying heat and pressure. Mostly, methods are relieved due to the reliability and efficiency of the technique.

- Adhesive Bonding: Adhesion bonding, which is to bond the copper foil onto the base. This method allows for more flexibility in terms of materials used but requires precise control to avoid issues like delamination.

Properties of Copper Clad Laminate (CCL)

CCL has various properties which are essentially key to its performance in electronic applications.

Here’s a simple breakdown of these properties:

Mechanical Properties

Mechanical property talks of the CCL yield strength and flexibility, it includes:

- Strength: This means that the CCL has to be rigid enough to mount the electronic components through physical stress that arises at the time of use or when the system is being handled.

- Flexibility: The amount of flexibility needed may vary depending on the kind of CCL, particularly for those flexible or rigid-flex circuits.

- Durability: The CCL shall have a reasonable service life under wear and tear, vibration, or mechanical impacts.

Electrical Properties

The electrical properties actually determine how the CCL conducts electricity in general, and hence the quality of the signals can be maintained accordingly:

- Dielectric Constant (Dk): This measures how well the CCL can insulate and store electrical energy. A lower Dk is better for high-speed and high-frequency applications because it reduces signal loss.

- Dissipation Factor (Df): This tells one how much energy is dissipated as heat by the dielectric as a result of signal transmission. A low dispersion factor concerns the minimal loss of energy, which is preferred, especially in high-speed circuits.

- Insulation Resistance: It is proper for stating how well a CCL can prevent the electrical currents from one layer from getting diffused into the adjoining layers. High insulation resistance ensures that signals don’t degrade and that the circuit works reliably.

Thermal Properties

Thermal characteristics are those properties of CCL that describe how they handle heat.

- Heat Resistance: CCL withstands the attack of either weathering or exposure to high temperatures without degrading. This becomes notably correct in the case of large Power Devices that produce considerable heat.

- Thermal Conductivity: This is a measure relating to how competently heat is transferred away from sensitive components by the CCL. Good thermal conductivity will ensure that there is no overheating but it runs effectively.

Chemical Resistance

Chemical resistance is one of the key aspects that ensure the CCL would last in place in different environments:

- Resistance to Chemicals: The CCL should resist damage from chemicals like solvents and acids. This helps it maintain its performance and integrity, especially in harsh or industrial environments.

These properties make CCL ideal for almost all kinds of electronic devices and ensure that these devices work optimally and with reliability in most conditions.

Applications of Copper Clad Laminate (CCL)

CCL has important applications in many electronic devices because it aids much in fabricating printed circuit boards.

Following is the application in different systems:

- Printed Circuit Boards (PCBs)

CCL stands for Copper Clad Laminate, which is the primary material for PCBs; without CCL, there is no PCB.

The copper layer attached to a CCL forms the connections between various portions of different electronic components, both in consumer electronics, like smartphones, computers, and home appliance products.

- Flexible Circuits

Applications for flexible CCLs include those in which the circuit requires bending, such as in flexible displays for wearable technologies and in devices with folding capacities in compact designs.

For devices that require pliancy, flexible CCLs make them lighter without losing the working conditions of the devices.

- Rigid-Flex Circuits

Rigid-flex CCLs combine both rigid and flexible parts into one circuit board. This proves to be more advantageous for devices containing rigid and pliable sections, such as medical instruments, aerospace technology, and military electronics.

It saves a lot of space and ensures that the circuit fits into positions that are very tight or complicated.

- High-Frequency Applications

Very high-speed circuits require high-frequency CCLs, which are typically used in telecom equipment and radio devices.

All these contribute to reduced signal losses and interference provided by the CCLs, very significant in line and reliable communication of high-speed data transmission.

- Consumer Electronics

CCL is applied in creating the essential circuit paths in everyday gadgets such as smartphones, tablets, and TVs so as to allow parts of the device to communicate and work with each other properly in every way, hence displaying good reliability and functioning well.

CCL Industry Standards

There are 2 CCL industry standards that you must know:

- IPC Standards: IPC (Institute of Printed Circuits) sets rules for designing and making PCBs and CCLs. These standards ensure that CCLs are reliable and perform well.

- UL Certification: UL (Underwriters Laboratories) tests and certifies CCLs for safety. This certification confirms that CCLs meet fire safety and quality standards.

Conclusion

CCL is undoubtedly the most vital material that enters into printed board preparation for any electronic device. It combines a base material with copper to create electrical pathways.

Varied types of CCL go with myriad applications of everyday gadgets and also to high-speed electronics. The understanding of how it is made and what its properties are is key in the selection of the appropriate CCL.