Chip Scale Package(CSP) Definition

Chip Scale Package (CSP) refers to a packaging technology where the package size does not exceed 20% of the chip size. To achieve this standard, unnecessary structures must be minimized, such as using standard high-power LEDs, removing ceramic heat sinks and connecting wires, metallizing the P and N terminals, and directly applying a phosphor layer over the LED.

FAQs

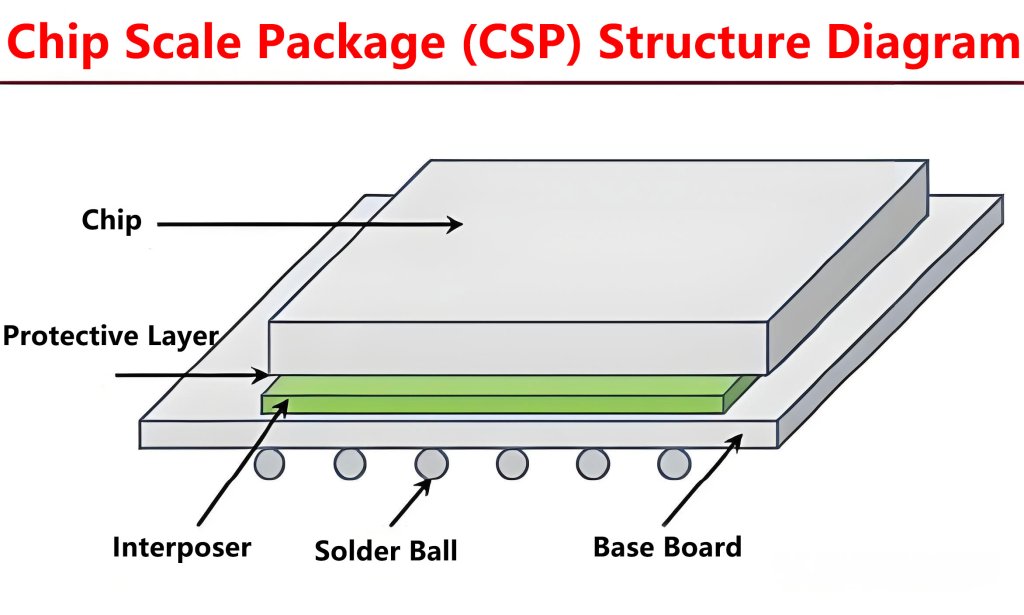

In this article, BGA refers to a 35-mm or larger device with 760-µm solder balls. The term CSP describes devices with 250-µm solder balls and an interposer layer between the die and solder balls. The overall package size of a CSP is typically no larger than 1.2 times the size of the silicon.

A chip scale package or chip-scale package (CSP) is a type of integrated circuit package. Top and bottom of a WL-CSP package sitting on the face of a U.S. penny. In the top-right, a SOT23 package is shown for comparison. Originally, CSP was the acronym for chip-size packaging.

*Source:https://en.wikipedia.org

Flip-chip refers to turning the chip upside down and attaching it to the substrate or lead frame. Compared with general CSP, the difference is that it uses bumps such as solder or copper pillars for interconnection instead of traditional wire bonding.

*Source:https://jhdpcb.com

Size and Weight: CSP is usually smaller and lighter than COB, suitable for applications with limited space, while COB may be more suitable for applications with less stringent packaging size requirements. Cost: COB usually has lower packaging costs than CSP because it does not require additional packaging shells.

*Source:http://sostron.com

Zero Defect

Quick-turn service

PCBA Manufacture

Learn how Keep Best can turn your designs into products.