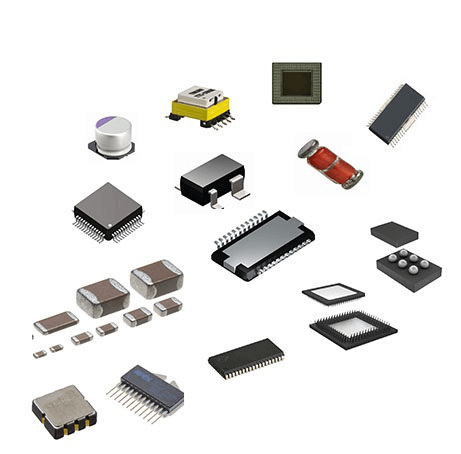

Surface Mount Device Definition

Surface Mount Devices (SMD) refer to electronic components that are mounted on printed circuit boards (PCBs) using Surface Mount Technology (SMT). Unlike traditional Through-Hole Technology (THT), SMDs are directly attached to the surface of the PCB without the need for drilling holes.

FAQs

SMD (surface mount device) sensors are the solution for temperature measurement applications where the sensor needs to be incorporated onto a printed circuit board (PCB). See this FAQ for how and why SMD's are used on PCB's.

*Source:https://kamet-trading.com

SMD components are typically more expensive than their through-hole counterparts due to their smaller size and the complexity of their manufacturing process. However, the use of SMDs can lead to cost savings in the assembly process due to their higher component density and more efficient assembly.

*Source:https://www.wevolver.com

SMD package types describe the physical characteristics of devices that use surface mount technology (SMT) for attaching electronic components directly to the surfaces of printed circuit boards (PCB). In other words, an SMD is an electronic component that attaches to a PCB with SMT.

*Source:https://www.zaxis.net

While surface-mount devices (SMDs) are secured only by solder on the surface of the board, through-hole component leads run through the board, allowing the components to withstand more environmental stress.

*Source:https://www.vishay.com

Zero Defect

Quick-turn service

PCBA Manufacture

Learn how Keep Best can turn your designs into products.