Want improved performance for your intelligent robots? It starts with custom PCBs that will fit in exactly with your requirements at the roots. Off-the-shelf options often can’t meet the precise needs of today’s advanced robotics.

So in this article, we are going to discuss customized PCBs for intelligent robots in detail. In this guide, you will learn what custom PCBs are, the benefits of customized PCBs for intelligent robots, and more in detail.

So, let’s get started.

What is a Custom PCB

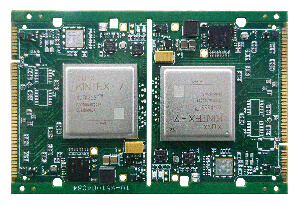

A Custom PCB is made specifically for a particular use, like in intelligent robots. Unlike the standard PCBs that are mass-produced and are the same for all, custom PCBs perfectly fit what a robot needs—like its size or how it works.

In advanced robots that call for mixes of sensors, processors, actuators, and other components interconnected to communicate with other devices, custom PCBs do play a very important role. They guarantee that all parts fit together exactly, are power-optimized, and function dependably under diverse conditions.

Custom PCBs allow designers to think outside the box and create robots custom-designed for specific functions. This is a way to get a much more reliable, efficient, and perfect robot in its designed application.

Advantages of Customized PCBs for Intelligent Robots

Customized PCBs have a number of advantages that are quite important in enhancing the capabilities and performance of intelligent robots.

- Perfect Fit and Integration:Custom designing of PCBs permits perfect fitting to unique layout and size requirements in intelligent robots. This ensures efficient usage of space inside a robot’s chassis, therefore allowing for better integration of components like sensors, processors, and actuators.

- Enhanced Performance: By tailoring the PCB design to specific operational needs, manufacturers can optimize factors such as power distribution, signal integrity, and heat dissipation. This results in improved overall performance and reliability of the robot in various operating conditions.

- Cost Efficiency: Even though the development cost of a custom PCB is higher compared to a standard one, this kind of board mainly contributes to cost-saving in the long run. They abolish the use of excess parts and decrease the routines of repair, minimize loss during production due to failures, and increase the life expectancy of the robot.

- Scalability and Future-Proofing: Custom PCB design can scale with any future upgrades or changes in the functionality of robots. A robot will then be able to move along with progressing technology or changing application requirements with time.

Components Required for Custom PCBs for Intelligent Robots

The following are major components usually found in custom-made PCBs for intelligent robots:

- Microcontrollers and Processors:These are the ‘brains’ of the robot, executing commands and processing data from sensors and actuators.

- Sensors:Sensors such as proximity sensors, gyroscopes, accelerometers, and cameras are crucial for gathering environmental data and enabling the robot to perceive its surroundings.

- Actuators:These are parts that convert an electrical signal to mechanical motion, thus allowing a robot to realize something physical. These include motors, servos, and actuators for limbs or grippers.

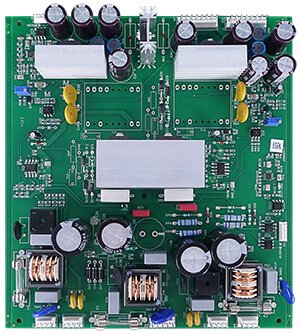

- Power Management Components:These could be power regulation circuits, voltage converters, and battery management systems that would ensure proper power distribution and management throughout the working of the robot.

- Communication Modules:Wireless communication modules, such as Wi-Fi, Bluetooth, Zigbee, or wired communication modules like Ethernet, are essential for communication of data between the robot and other external devices or networks.

- Interface Circuitry:These are interfaces to connect external peripherals or modules. This includes USB ports, display HDMI interfaces, specialized connectors which reach out for additional sensors or actuators, and so on.

Each of these components contributes essentially to the functionality and performance of intelligent robots.

Factors to Consider in Designing Custom PCBs

Designing custom PCBs for smart robots involves thinking about several important factors to make sure they work well and last long:

- Size and Shape:The PCB needs to fit inside the robot without taking up too much space or getting in the way of other parts.

- Choosing the Right Parts:Picking parts that can handle the robot’s job and work in different conditions is crucial. They need to match what the robot needs to do and last a long time.

- Keeping Signals Strong:Making sure signals between parts stay strong helps the robot work reliably. This means planning how wires are laid out and reducing any interference.

- Managing Power:Making sure every part gets the right amount of power keeps the robot running smoothly. Systems that manage power and rechargeable batteries are important for keeping the robot going.

- Handling Heat:Robots can get hot, so the PCB design should help keep things cool. This includes using special parts and designs that can handle heat well.

By thinking about these things when designing custom PCBs, designers can make robots that work better, last longer, and do more things.

How Custom PCBs Enhance the Functionality of Smart Robots

Custom PCBs play a crucial role in enhancing the functionality and performance of smart robots in several key ways:

- Better Performance:Custom PCBs are made to fit exactly what a robot needs. They help sensors, motors, and other parts work together smoothly, making the robot more accurate and reliable.

- Saving Power:Custom PCBs manage power well, which means robots can run longer without needing to recharge. This is important for robots that need to work for a long time without stopping.

- Special Connections:Custom PCBs can have special ways to connect to other devices, like using Wi-Fi or Bluetooth. This makes it easier for robots to communicate and work with other machines.

- Adaptable and Upgradeable: As robots get better, custom PCBs can be changed or added to make the robot do more things. This helps keep robots useful as technology improves.

Conclusion

Customized PCBs are essential for making smart robots work better. They help robots perform tasks more accurately and reliably by fitting perfectly and managing power efficiently. These custom designs also save money in the long run by reducing repairs and improving durability.