Are you just starting your journey in PCB design, yet confused between different types of PCBs? Well, don’t feel left out, as understanding the types of PCB is not a child’s play.

Many beginners face difficulties with this, and if you are one of them, you are definitely in the right place. Below we explain in detail the various types of printed circuit boards.

Whether you are a beginner or an expert, the way to make your electronic dreams come true is all about understanding PCB types.

So let’s begin.

Understanding Printed Circuit Boards

Well, the foundation of all modern electronic gadgets rests upon PCBs since they form the backbone on which our gadgets work.

You can consider them as intricate networks of conductive pathways that facilitate the flow of electricity between various components like resistors, capacitors, and integrated circuits. Without PCBs, the complex inner workings of our devices would be nothing more than a tangled mess of wires.

As you know, there are different types of PCBs for various applications. Everything is categorized based on the rigidity, layers, functionality, among others, to ensure that each kind of PCB is best suited for the application.

Whether you are dealing with a simple low-power circuit or a high-performance electronic device, there’s a PCB type designed.

Let’s discuss different PCB types in detail below.

Different Types of PCBs

There are two major types of PCBs:

1. Rigid PCBs

Rigid PCBs provide a firm and stiff platform for mounting electronic components, ensuring durability and reliability across diversified applications.

They are built out of a substrate, such as fiberglass, which is quite stiff and provides high strength for the components, hence offering resistance to any kind of flexing or bending.

Rigid PCBs are applied in equipment that requires high stability and rigidity, for instance in industrial controls, power supplies, and consumer electronics.

2. Flex PCBs

Flexible PCBs, on the other hand, offer the unique advantage of being able to bend and flex without compromising functionality.

This is because they are being produced in flexible materials: for instance, polyimide or polyester. Thus, they can fit into any weird shape and tight space.

Flexible PCBs is a very convenient interconnect option for applications involving relative movement or having space hydro limitations, including but not limited to wearable electronic devices, medical devices, and automotive systems.

Understanding Layer Count:

Besides rigidity, layer count is another critical element in PCB design, determining the complexity and functionality of the board.

There are three broad categories of PCBs based on this category:

1. Single Sided PCBs

In a single-sided board, the conductive traces are noticeable only on one side of the board, whereas on the opposite side of the board, the components are soldered.

These boards are simple in design, and inexpensive production is quite possible, so it is applicable to elementary electronic circuits and devices of low power.

2. Double-Sided PCBs

Two-sided PCBs are designed with conducting traces on both sides of the board; they are more versatile in component and density applications.

Having mounted components on either side, complex circuitry can be easily accommodated, and so these are very prevalent. These find application in a huge number of electronic devices such as power supplies, consumer electronics, and industrial controls.

3. Multilayer PCBs

Multilayer PCBs are made by sandwiching many layers of conductive material between insulating materials, which consequently permit very complex circuits with a high density of components.

They are used in high performance devices where space is limited: such as smartphones, computers, and networking equipment. The additional number of layers also allows better signal integrity and improved electromagnetic compatibility.

It’s necessary to understand the difference between these types in order to select the appropriate board for your application. Otherwise, performance and reliability will not match at all.

The Most Common PCB Types

So here are the most common PCB types that you may need to design for different applications.

1.) Rigid PCBs

Here are the 3 subtypes of Rigid PCBs that are used for different purposes and applications:

- Single-Sided PCBs

Single-sided PCB is one of the basic kinds of printed circuit boards, with conductive traces on one side of the board, while components are soldered on the other side.

This simple design makes it cost-effective in terms of cost and easy to manufacture, thus perfectly suited for applications that demand simple electronic circuits and low-power devices.

Single-sided PCBs are economical and easy to work with, but they limit the complexity and density of designs that cannot be tackled by complex or high-performance applications.

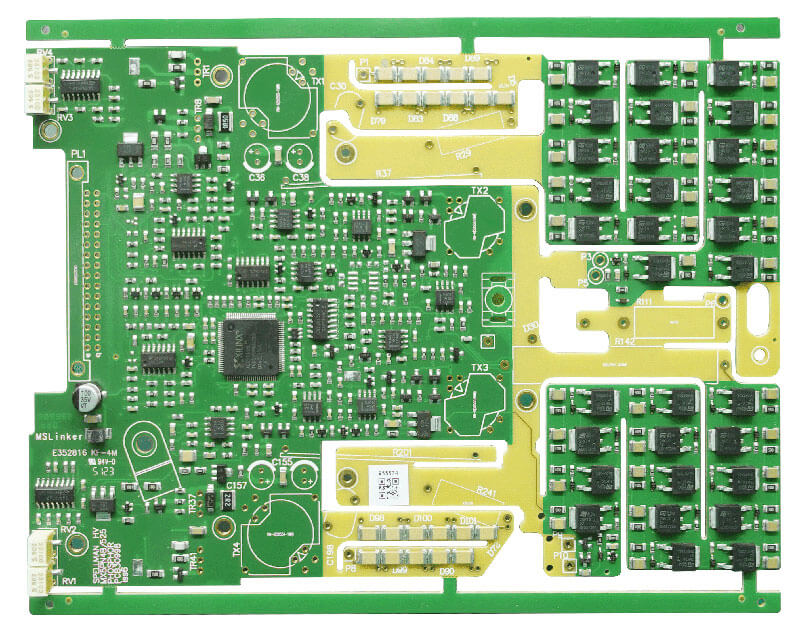

- Double-Sided PCBs

While the single-sided PCBs have conductive traces on only one side, double-sided PCBs have them on both sides, making them versatile when it comes to the density of components.

This is very appropriate in a wide range of consumer electronic applications, power supplies, industrial control, and automotive systems. There is more complex circuitry with an increased number and variety of electronic parts.

Even if the manufacturing cost may be slightly higher than that of single-sided PCBs, the benefits that arise from increased functionality and performance often override the expense.

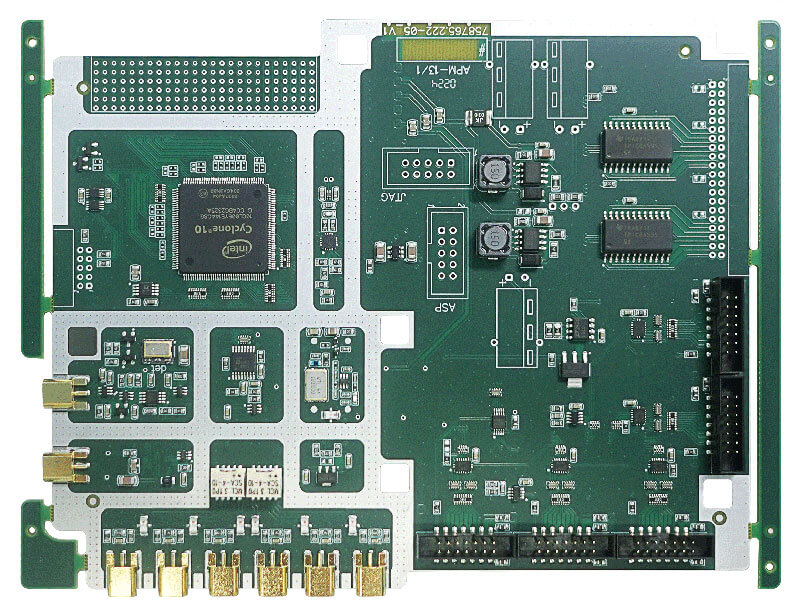

- Multilayer PCBs

Another level of complexity and functionality is brought about by a multilayered printed circuit board, which has two or more layers of conductive material placed in between layers of insulating material.

This allows the possibility of fabricating much more complex circuits with a significantly higher density of components while maintaining signal integrity and reducing electromagnetic interference.

This is one of the reasons multilayer PCBs are used in state-of-the-art electronic devices, which include smartphones, computers, networking devices, and medical equipment—where space is a constraint but performance is at its peak.

However, the most complex and expensive PCB type is the multilayer PCB. Its production shows a high level of skill and precision, reflecting the high quality of these high-performance boards.

2.) Flexible PCBs

Here are the 3 subtypes of flexible PCBs that are used for different purposes and applications:

- Single-Sided Flexible PCBs

Single-sided flexible PCBs are crafted from flexible materials like polyimide or polyester, allowing them to bend and conform to irregular shapes with ease.

This characteristic makes them highly amenable to hinged devices, wearable electronics, and flexible displays.

While single-sided flexible PCBs offer versatility and lightweight design, they are limited in terms of circuit complexity compared to rigid PCBs.

- Double-Sided Flexible PCBs

A flexible double-sided PCB is a two-layered flexible board with conductive tracks on both of its surfaces. In brief, a flexible double-sided PCB allows complex circuitry and function.

This makes them suitable for use in advanced electronics, specifically cameras, medical devices, and aerospace systems where flexibility and high performance are demanded.

Besides the added value, thanks to the enhanced capabilities, double-sided flexible PCBs also normally undergo increased manufacturing costs due to the complex construction process.

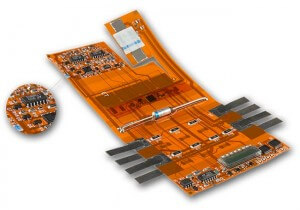

- Rigid-Flex PCBs

Rigid-flex PCBs allow for the incorporation of the best of both worlds: rigid and flexible sections in one board. Thanks to this very special construction, an unmatched variety in design can be achieved with the help of designers who can use rigid and flexible elements to make one coherent design from one piece.

Robotic devices, automotive electronics, portable equipment, and aerospace systems are flex-rigid PCB applications among many others that demand both.

But the production process is rather complicated and expensive due to the precision and high level of expertise necessary in order to achieve such boards.

3.) Specialized PCB Types for Advanced Applications

Besides these 2 major PCB types, there are some advanced PCB types specially designed for some specific applications:

- High-Density Interconnect (HDI) PCBs:High-density interconnect PCBs provide ultra-fine features and high layer counts to support maximum miniaturization and performance in advanced electronics.

- Metal-Core PCBs:Boards with a metal core are used for efficiency in heat dissipation and can be applied to high-power applications.

- Ceramic PCBs:High-temperature and high-frequency applications use ceramic PCBs, whose properties include high thermal conductivity and excellent mechanical properties to ensure reliability.

So these are all the different types of PCBs. Every category has some uniqueness and supposed benefits appropriate for applications ranging from basic electronic circuits to advanced aerospace systems.

Conclusion

In conclusion, understanding the different types of PCBs is crucial for both beginners and experts in the field of electronics. From rigid to flexible PCBs, each one of them has its advantages, disadvantages, and applications.

Selecting the proper type of PCB is important while working on both simple circuits and high-performance devices, to ensure that optimum performance and reliability are achieved.